2020. 2. 23. 01:35ㆍ카테고리 없음

No matter what the age of a building there is one simple universal truth; water is a buildings worst enemy. As the saying goes, if you can keep the water out & away from the building, it can last forever. One of the most overlooked areas unfortunately happens to be your homes primary defense; the roof.

How To Install Roof Flashing Against A Wall

Not only does it get, but then we have. Then to add the proverbial cherry on top, we have homeowners that barely look up, much less take care of any needed.

If you wish to know the code minimums for each type of roofing, they can be found in the 2009 IRC under section R905. They generally fall under.X.8 or the “Flashings” heading for each type.

I must quickly point out that felt aka tar paper is not an option listed & you should refer to and install in “accordance with manufacturer’s installation instructions”Valley Flashing:I don’t know if it is just this area, or what but I see so many issues revolve around the valleys. Maybe it is because they like doing the “woven” style out here while out west we trimmed the shingles back & used a “W” Flashing detail. No matter which style you prefer, you should use a full 3’ wide layer of Ice & Water Membrane (I&W) in the valley.This is a diagram of my preferred method. You should first clean out the valley & lay down a 3’ strip of Ice & Water membrane & follow this up with a W Valley style flashing. I generally do this to help prevent the dreaded “what part of don’t walk in the valley didn’t you understand?” While some like trimming down 3-tab shingles for a starter strip (or add tar), I generally use starter strip & make sure it is laid out at the angle I need. (At the top of the valley you should have a 2+” gap & it should increase by 1/8” of an inch for every foot of valley).

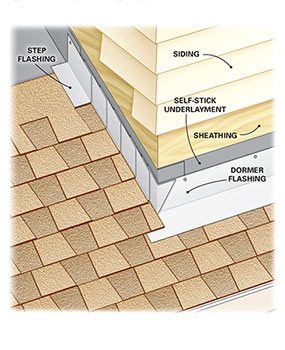

Penny Wise but Pound Foolish x 2:Ah yes the dreaded, who needs to install step flashing or even a kick out flashing? Well in order to clear this up, the minimum you can do per code is; “ R905.2.8.3 Sidewall flashing. Flashing against a vertical sidewall shall be by the step-flashing method. The flashing shall be a minimum of 4 inches (102 mm) high and 4 inches (102 mm) wide. At the end of the vertical sidewall the step flashing shall be turned out in a manner that directs water away from the wall and onto the roof and/or gutter.”While this is a nice diagram of how these flashings work don’t forget our “Think like a drop of water does.” Do you see the issue(s)???.We will actually get to the 2 nd item in the next section, but you might notice the part we struck through – yeah that is not a good practice as any water that gets behind or under the flashings now only has one way to go & that is inside the structure.

I generally prefer to wrap I&W up the vertical wall at least 6” to 8” and make sure it extends past the kick-out flashing. So why not just use Ice & Water as the flashing? Well the issue is UV rays degrading the material.

As most sidings specify an inch or two gap that must be covered by another material that won’t be affected by the UV rays.Drip Edge:If you are going to use metal fascia, you really do need to use a drip edge. In fact I really can’t think of any reason not to use one. With that times have changed mainly driven by new materials and lessons learned with hurricanes, ice dams and the like. While we used to install the drip edge directly to the sheathing & then covered that with felt that no longer flies as most manufacturers require that the drip edge be placed over I&W.

Unfortunately as we pointed out in an earlier piece most people stop the I&W shield short allowing for water to soak into the edge of the sheathing &/or into the fascia.The best method now to protect the whole structure is to use a 6” strip of I&W or self-stick membrane which wraps over the sheathing & onto the fascia. With this the drip edge should completely cover the front of this membrane.

The final step is cover over this with I&W, felt or a synthetic overlay. If you really would like a belt & suspenders approach (or you quite simply live in a coastal or high wind area) you may wish to follow Florida’s example & tape all the sheathing seams before applying the overlay.

If conditions are right, new shingles laid over old shingles can be just as attractive and durable as shingles laid on bare sheathing.Installation is easier than for a tear-off job because you can use the existing shingles as guides for laying the new ones. But you must take care to install the shingles correctly so they lie flat.

And a good job involves installing new flashings rather than relying on the existing ones.Reroof jobs are sometimes done without replacing flashings. However installing new flashings—including special drip-edge flashings made for reroofing—will ensure a tight seal and a long life. Some roofers install a layer of waterproof shingle underlayment (WSU) over the existing shingles at the eave end, as would be done for a roof laid on bare sheathing. This provides added protection against.Asphalt shingles can be laid over cedar shakes or shingles, a job best left to pros. Beveled wood pieces called 'horsefeathers' must be laid along the thick edges of the shakes to make a fairly flat surface.